|

DECEMBER 2016

|

109

CONNECT

on the cooler, so the logo is seen

every time a person goes into the

cooler for a beverage.”

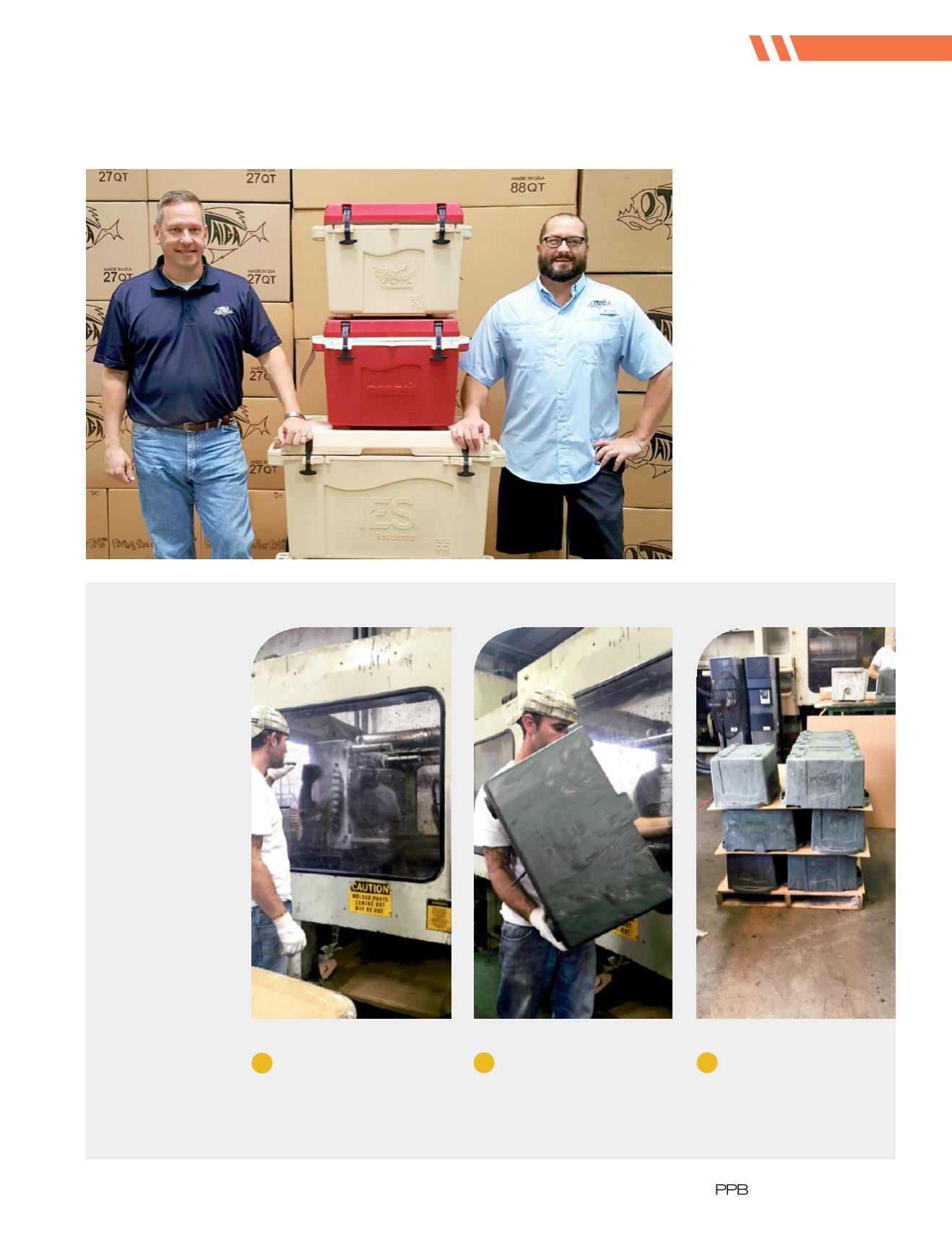

The development process—

including the development

and manufacture of injection

molding equipment—took

roughly eight months, says

Hohenshelt. Taiga’s hard-sided

coolers come in standard white

and tan and in camouflage

shades, but the company has

plans to include more styles,

Read on

to learn

how Taiga’s

custom

coolers are

created.

1

A machine operator waits for the

custom injection molding machine to

finish before releasing the cooler.

2

Taiga’s injection molding process

allows for images such as logos and

brand names to be incorporated

directly into the cooler’s plastic shell.

3

Cooler shells bearing Taiga’s

company logo are stacked in

preparation for assembly.

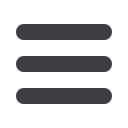

John Hohenshelt, left, and

co-owner Adam Artho are

leaving their mark on the

custom cooler business.