JUNE 2015 •

PPB

• 89

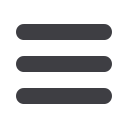

The material is set up and cut

on the cutting press; a die is

pulled, and the stock is cut

according to the order.

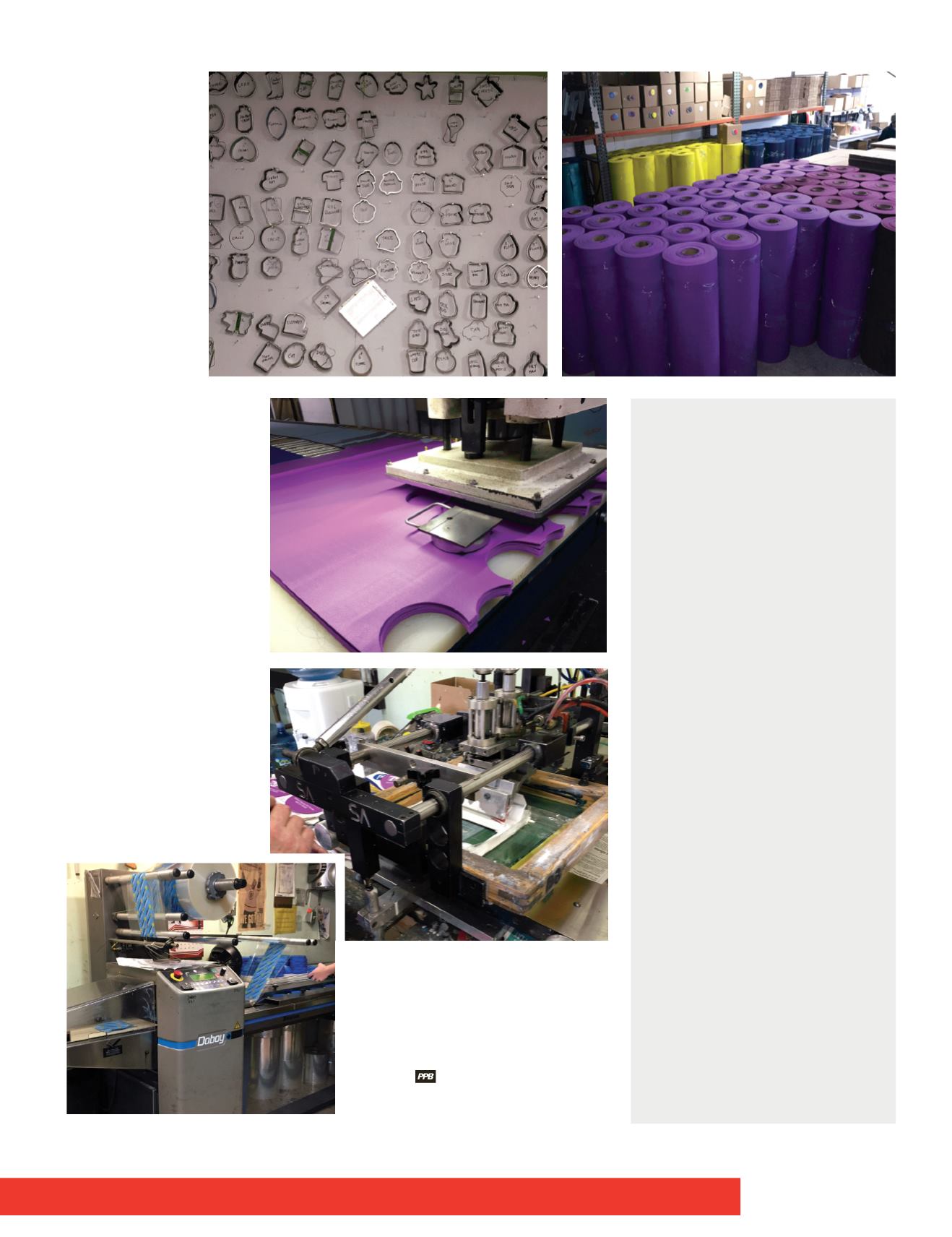

The purchase order and die-cut

jar openers arrive in the print-

ing department, and the open-

ers are set up on the press.

Once printed, the jar openers are

individually polybagged, boxed and

shipped.

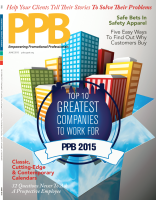

Purchase orders are

entered and

processed according

to requested ship

dates. While the

screen or digital art

files are being pro-

duced, a message is

dispatched to the die-

cutting dept, listing

the material, color and

quantity needed to fill

the order. A die is

selected from the fac-

tory’s collection of

shapes.

ABOUT AMERICANNA

COMPANY

Founding date

1983

Principal

Robert Hayes,

owner/president

Number of orders filled per

year

Nearly 10,000

Size of production facility

15,000 square feet

Number of employees

29

Types of specialized equip-

ment

In addition to its 180

custom dies, Americanna

employs UV digital equipment

for decorating.

Notable accomplishments

Americanna says it is the

nation’s leading jar opener

manufacturer, and the first

industry supplier to offer a full-

color imprint directly on a grip-

per surface.

Top 3 products among clients

Five-inch circle jar openers

Four-inch circle natural cork

coasters

Products made from recycled

materials