APRIL 2015 •

PPB

• 27

SEEING

GREEN

Sales, still makes the paper one sheet at a time. Over the past

20 years she has worked with thousands of companies who

have purchased her product, and she says the company continu-

ally puts its creative energy into expanding the product line to

appeal to a wider variety of end users. “Some of the largest cor-

porations in the world have used our handmade paper because

it gives them the distinction of showing concern for the envi-

ronment by choosing a recycled, recyclable and biodegradable

product,” she says.

Felson says she has seen the market swing from about 10 to

15 years ago, when companies were using seed paper to “appear

to be environmentally friendly,” to today when it is a priority

and real concern for many corporations. “More and more peo-

ple are looking to go green.” Also, Felson says she is finding

that “Made in the USA” is becoming a label of distinction, as

local manufacturing can be observed and tracked. “All the seeds

we use are from a U.S. supplier. Each batch of seeds we buy

comes with a purity and germination report.”

Creating new and distinctive merchandise is one of their

biggest challenges and at the same time one of their biggest

rewards, Felson says. “Our creativity has always been our

strongest marketing tool. We have been able to produce unique,

one-of-a-kind programs by utilizing product modifications,

changes to the production process and sustainable packaging.”

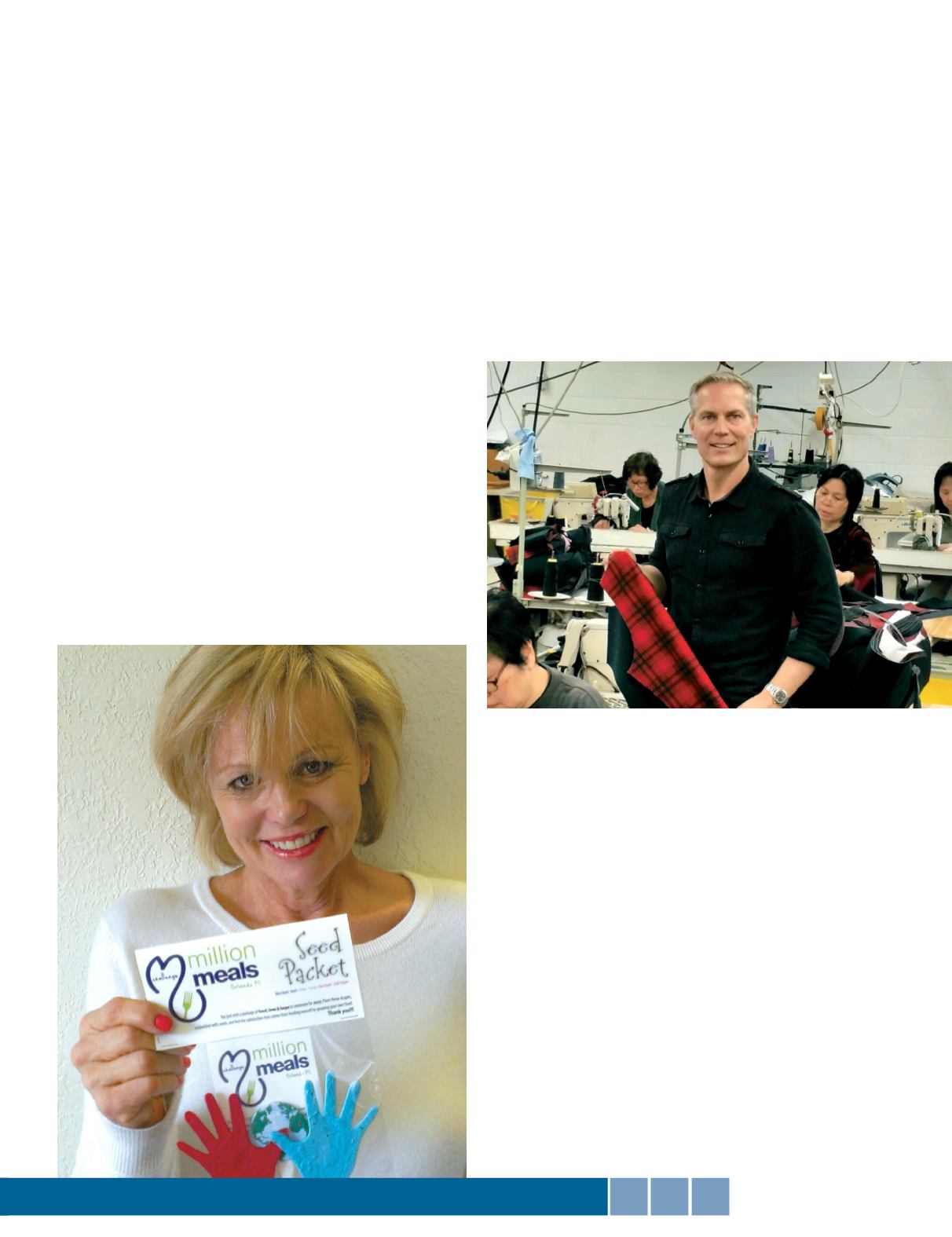

ECO-RESPONSIBLE AND FASHION FORWARD

Creating fashionable, stylish apparel from recycled plastic

PET (polyethylene teraphthalate) bottles was a visionary idea

when it was launched by supplier Boardroom Eco® Apparel

(UPIC: 214844) in 2001. Since that time, the apparel design

and manufacturing company, located in Vancouver, British

Columbia, which specializes in custom manufacturing, has

introduced low-impact recycled polyester fabrics and closed-

loop apparel recycling.

The company, founded in 1996 by Mark Trotzuk and Lan

Tran, started by offering fashion-forward designs in corporate

promotional apparel and uniforms. Its specialty was researching

the latest fabrics and styles to bring new and exciting apparel

collections to the promotional products industry. But about

eight years ago, Trotzuk, now president, decided to change the

company’s direction.

“Knowing that what I was doing for a living was not that

environmentally friendly, I felt I was going about it the wrong

way.” Instead of manufacturing apparel from traditional fibers,

he created a system that melts pellets made from clean, flaked

plastic water bottles, and then extrudes them into a fiber that

can be processed into fabric for apparel and other items. The

company website states that using the recycled polyester fiber

rather than virgin polyester uses 85 percent less energy and 90

percent less water, and it produces 65 percent less sulfur dioxide

emissions during the process.

To complete the closed-loop process, used garments (100

percent polyester and/or recycled polyester) can be returned to

the company to be recycled into new 100-percent recycled

polyester apparel.

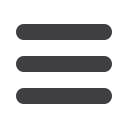

Lauri Felson

Mark Trotzuk