FIVE MINUTES WITH

Jennifer Wolanik

Marketing Expert at Quality Logo Products

|

APRIL2017

|

59

THINK

A NewDimension

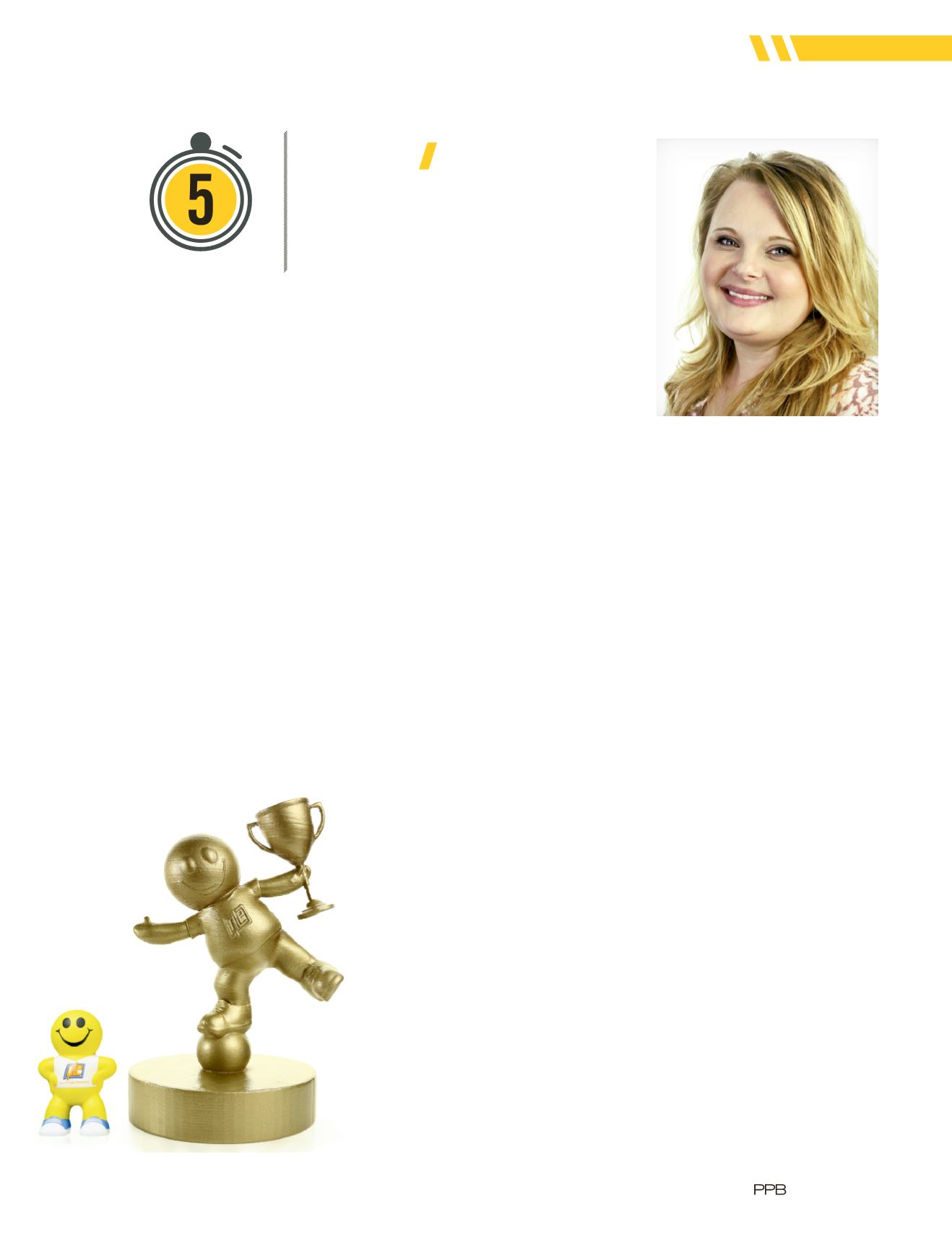

Looking for a way to kick its supplier awards up a notch, distributor Quality Logo Products in

Chicago, Illinois, broke the mold with custom 3D-printed trophies. Jennifer Wolanik, QLP’s

resident marketing expert, explains the process of bringing the company’s mascot to life as an

award trophy.

PPB

What prompted the idea to produce

your company’s supplier awards as

3D-printed statues?

Wolanik

Our company culture is one of

always pushing internal projects to the next

level in terms of creativity, method and

uniqueness. Our president, Bret Bonnet,

and I had discussed the initial possibility

of 3D printing with our trophies as the next

step in the evolution of our annual Supplier

Awards trophies.

We started with our in-house design

team, producing several sketches based on

a group brainstorm. This option allowed for

our sketches to be almost limitless with our

creative team unleashing all possibilities for

a new trophy design—not that we’ve ever

made anything “standard” in the past.

PPB

How many did you commission, and

what was the time frame for production, from

illustration to delivery?

Wolanik

We commissioned a local printer

to produce a total of 10 trophies, first

through 10th place versions. The sizes

ranged from six inches tall to more than

10 inches tall, which did restrict us a bit in

finding a printer that could accommodate

the largest size.

The time frame for having the final

products delivered was about two weeks,

from the initial sketch to receiving the

3D-rendered files to the final pick-up from

the printer. The trophies were printed with

white PLA (polylactic acid) plastic, which we

then painted in-house in the final colors for

each trophy placement.

PPB

What has been your company’s

experience with 3D-printed promotional

items, if any? How did you come to connect

with your local printer?

Wolanik

Prior to this experience, we had

never commissioned or had direct experience

with 3D-printed items. We do have some

resident hobbyists who have experimented

with this technology on different scales, but

never to this level or size.

We connected to a local printer through

3DHubs.com,a website that helps connect

over one billion people worldwide with

3D printer technology. This allowed us a

personal experience and the opportunity

to ask questions versus ordering through a

standard, detached website.

PPB

What did you learn about the process

that you found fascinating and/or surprising?

Wolanik

The most intriguing part, to us, was

seeing our 2D design transform into a molded

3D shape in preparation for the printing. The

printer did notify us after receiving the files

that some of the elements extended past a

30-degree angle and would therefore need

some support scaffolding, which would be

removed after the print was finished.

The scaffolding is extra meshed structure

extending from the base to the bottom of

these angled parts. As the plastic cools

down, the support scaffolding helps to hold

the printed shape and stop any sag that may

occur with larger shapes. It was such an

unfamiliar process to us at the beginning but

we honestly felt like pros learning about the

lingo and process along the way.

PPB

Do you have plans to offer 3D

merchandise to clients in the future, or have

you already begun offering any items?

Wolanik

Though we do not currently offer

3D-branded merchandise to our customers,

The trophies

for the Supplier

Awards ranged

from six inches

to more than

10 inches tall.