90 •

PPB

• AUGUST 2016

CONNECT

FACTORY

FLOOR

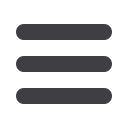

2. After the pieces are

trimmed,

they are placed in a

kiln for the fusing process. The

artistic glass is brought to a specific

temperature so the two layers of

glass become one. The part is then

placed on top of a form and

placed back inside the kiln where it

is processed a second time until

the glass falls into the shape of the

form. This fusing and slumping

step is a two-day process.

Jen Alexander is associate editor for

PPB.

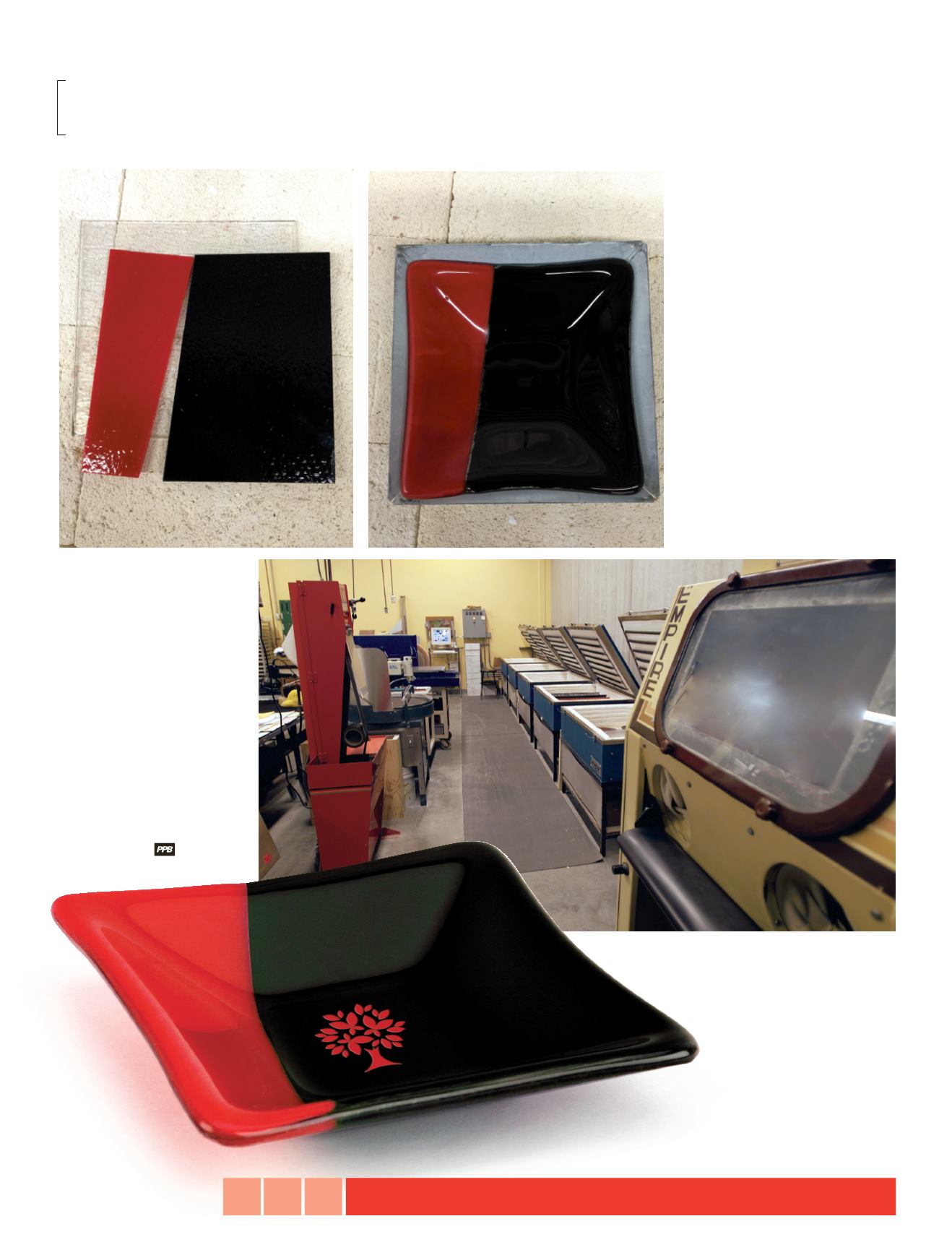

3. The customer’s artwork

is

then transferred onto the surface of

the artistic glass using Advance’s

sandblasting process. If the cus-

tomer chooses colorfill, the cavity is

sandblasted deeper to contain the

colorfilling ink. The finished piece is

then cleaned and placed into a

two-piece gift box with protective

precision-cut foam.