ADVANCE CORPORATION

AUGUST 2016 •

PPB

• 89

“Advance has been witness to a major

shift in the industry,” says Wilson. The shift,

she says, is moving away from a traditional

type of award to a more customized, unique

style that is designed specifically for a recipi-

ent or program.

“This one-of-a-kind award feature is the

latest trend and a perfect fit for Advance.

Our niche is to offer a wide array of standard

products that can be made to order as pic-

tured, or customized in-house to meet the

needs of our customers,” she says.

Advance’s house designers work closely

with the sales team to create conceptual lay-

outs that provide a virtual illustration of the

product options, and newer equipment

allows the supplier to offer larger format

products with shorter lead times. “Our

skilled team of craftsmen has attended some

of the best technical trade schools and uni-

versities,”Wilson says.

The top three products among Advance’s

clients currently are traditional wall-mounted

awards, framed and matted wall awards, and

full-color metal or acrylic awards. “Our per-

petual awards and donor wall units are gain-

ing in popularity,” adds Wilson

“We produce all the standard items pic-

tured in our catalog in our manufacturing

facility in Cottage Grove,” she says. “We

purchase crystal and glass blanks that we

personalize, but all of our artistic glass

awards are made from blank sheet stock

which is cut, fused, slumped and etched in-

house. All of our graphic design is also done

in-house.”

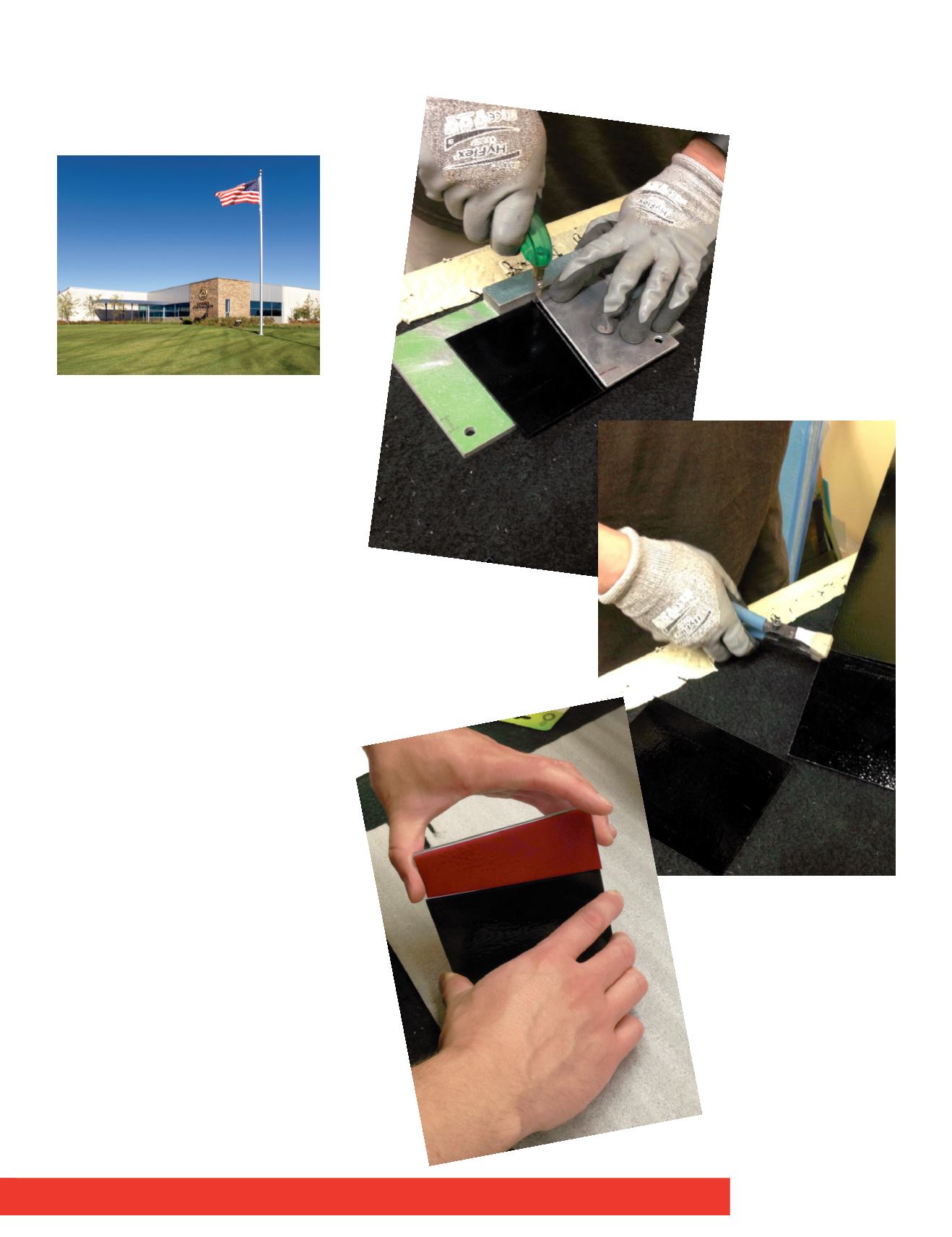

Read on to learn how pieces from

Advance Corp.’s artistic glass desk accessory

collection are crafted.

1. The production process

uses full layers of artistic glass,

depending on the customer’s

choice of color. Pieces are hand-

cut and trimmed to size.

Continued on next page