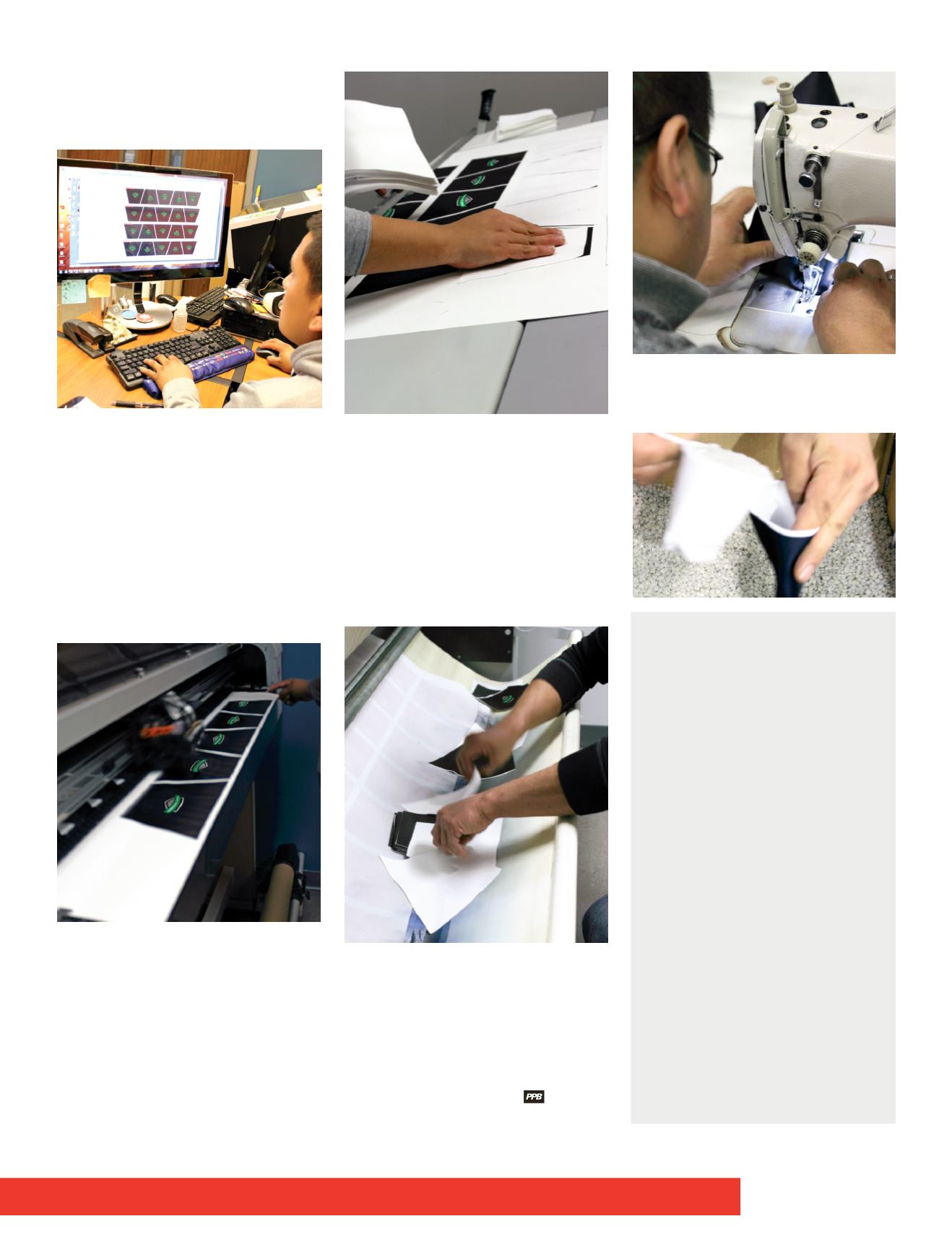

color-matches the provided artwork to the

customer’s specified PMS color, ensuring the

best possible match.

A sample is printed, then it is pressed

(dye sublimated). In-house color experts use

the most advanced color-analyzing tools to

ensure that the CMYK color on the finished

product is the optimal match to the cus-

tomer-specified PMS color. Once the product

has passed this color quality-control point,

the printing begins.

While the full-color digital print is made,

the microfiber is moved to the preparation

area and is cut to the specified size. To ensure

quality and consistency of the shape, the

optimal number of microfiber layers are cut

simultaneously.

Once the printing is completed, the proj-

ect moves to the pressing stage. After con-

ducting the necessary tests, a dye-sublimation

technician sets up the printed reel of paper

on the press and carefully aligns the pre-cut

pieces of microfiber to the printed artwork.

The cut pieces move to a master sewer,

who sews the Wedge almost to completion.

The Wedge is then filled and finished with

the final stitching up the back.

APRIL 2015 •

PPB

• 93

Toddy Gear’s sublimation technician care-

fully aligns the pre-cut pieces of microfiber

to the printed artwork.

The Wedge™ fabric is color matched and

digitally printed.

The material is fed through the press and

the pre-cut pieces are manually removed

from the press as they are finished.

A master sewer stitches the fabric (above)

before it is sent to be filled (below) and

finished with the final stitches.

ABOUT TODDY GEAR

Founding date

2011

Principal

Todd Gabel, President

Size of production facility

50,000 square feet

Types of specialized equip-

ment

Toddy Gear has six types

of specialized equipment for

printing, dye sublimation, cut-

ting and sewing.

Notable accomplishments

This

year the supplier introduced the

Smart Pouch Zip, a dual-sided

microfiber pouch decorated

with full color-full bleed. The

supplier also entered the UV

printing arena in promotional

products the same month, intro-

ducing a UV-printed full-color,

full-wrap power bank.

A print production technician prepares The

Wedge™ for print.