The softness and printability of a

cotton t-shirt greatly depend on

how it’s processed. There are two

primary types of yarn used to make

t-shirts: open end and ring spun. The

difference between the two comes

from the yarn-spinning method.

Open-end cotton yarns typically

use shorter-length cotton fibers and

yield a fabric that has a drier or crisper

hand. Open-end yarns tend to be

coarser, more loosely bound and with

rougher thread.

Ring-spun yarns have longer,

staple-length fibers that require two

steps in the manufacturing process

versus one step used for open-end

yarn. This increases the labor required,

and therefore is one factor in their

higher price.

There are two techniques used to

process yarn: carding and combing.

Carding is just like it sounds: moving

a card over the yarns. It doesn’t really

align the threads, and it doesn’t

eliminate the shorter, roving fibers.

Think of it in terms of combing

your hair with a comb or a card. The

comb is going to sink in and align the

strands so you’ll have a smoother,

cleaner look as opposed to a card that

is just skimming the top. Combing

also breaks the fibers apart, adding to

the softness of the garment.

The gauge or thickness of the yarn

is referred to as “singles.” The higher

the number, the finer the yarn. So, 30

singles is thinner than 20 singles. The

finer the yarns used, the smoother the

surface of the fabric and the softer to

the touch.

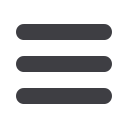

An add-on that can enhance the look

of a decorated garment for a nominal

increase in cost is printing over the zipper.

This offers the potential of featuring a

more eye-catching design increasing

the perceived value of the product and

offering greater customer satisfaction.

This design is an example of a discharge

print. When screen printing on dark

colors, a white underbase must be

laid down first as a foundation for the

design. This layer also adds weight to

the ‘hand’ of the shirt. An alternative

process uses discharge inks, which

bleach out the color of the shirt,

leaving a white or neutral area for the

design to be printed on. Because no

underbase is needed, the shirt has a

softer hand. In quantities between 48

and 200 pieces, discharge printing can

lower the overall cost of the product.

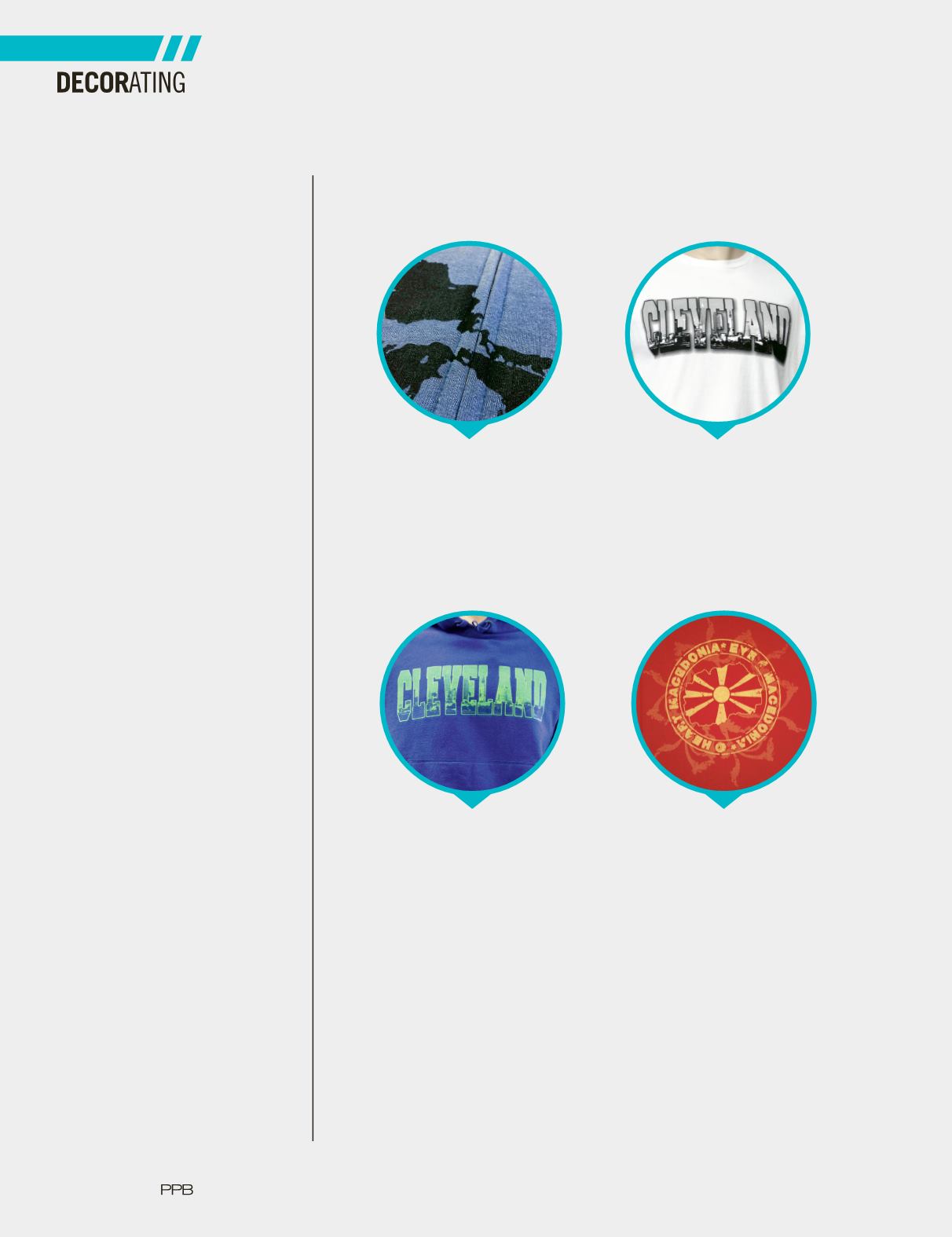

Through the use of halftones, it’s

possible to create gradients of the same

color, giving the print a multicolor look

while still only using one color. As each

color costs more when screen printing,

this is a low-cost way to create a more

eye-catching design.

This garment uses several techniques

to lower the cost while increasing the

attractiveness of the overall design.

Using a distressed effect eliminates

the need for a white underbase, which

would normally add to the cost of the

print and create a heavier ‘hand.’

The process also allows for a thinner

deposit of ink, which makes for a

softer-feeling print. Halftones are also

used to create gradients of the single

color, lending a multicolor look without

the cost of additional screens.

What Makes

One T-Shirt

BetterThan

Another?

Four Low-Cost Decorating Ideas

Photos provided by Blue Moon Promotional

22

|

JUNE 2017

|

INNOVATE