ABOUT UNIONWEAR

Founding date

1992

Principal

Mitch Cahn

Number of orders filled

per year

5,000

Number of employees

140

Size of production facility

70,000 square feet

140 sewing machine operators

Dedicated production lines

Baseball caps

Promotional tote bags

High-end tote bags

Military packs

Bucket and boonie hats

Patrol caps

Duffels, attachés, messenger

bags and backpacks

Types of specialized equipment

Hat taping machine

Robotic blocking unit

Sweatband-making machine

Double-needle hat taping

machine

Bucket-brim stitching machine

Hydraulic die-cutting clicker

Tajima embroidery machines

AS Technologies roll fuser

Zipper

Automated web-cutting

machinery

Programmable tackers

Programmable box stitchers

Roll-to-roll zipper-to-gusset

attach

Self handle machinery

Roll slitter for making handles

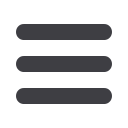

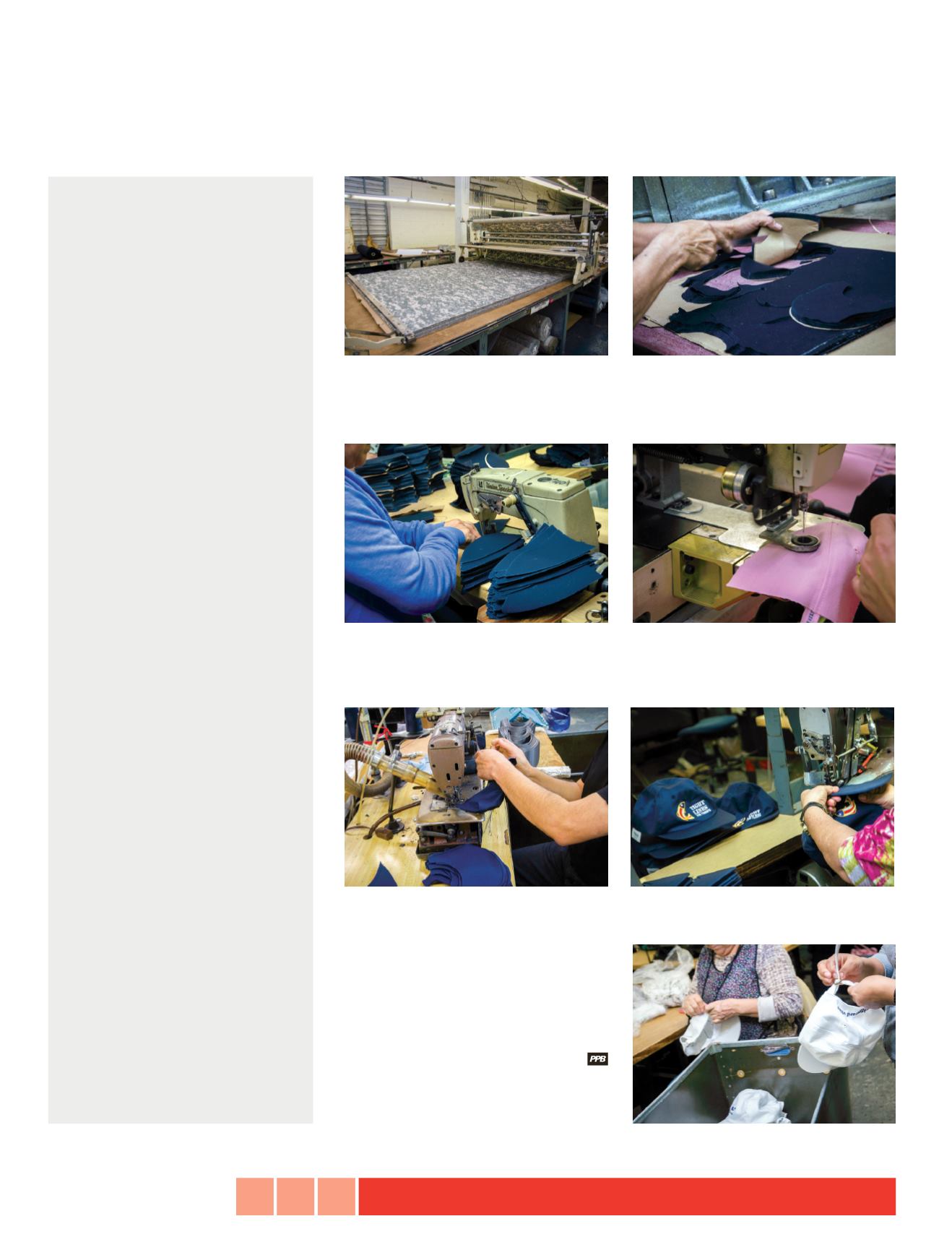

The caps begin as a roll of fabric, which is drawn out and cut for the quantity needed per

order. Each panel of the cap is then die-cut according to the type of cap it will be—struc-

tured, unstructured and fitted are a few styles Unionwear makes.

88 •

PPB

• DECEMBER 2015

CONNECT

our facility,” says Bronson.

“Our experience in making both hats and

bags has benefitted the production of both

products,” he adds. “In addition, we have

become experts in decorating unfinished hat

and bag parts, which enables us to get much

better quality, larger embroidery fields and

lower prices.”

Read on to see how Unionwear pieces

together its popular line of hats.

Jen Alexander is associate editor for

PPB.

Visors are produced and attached to the crowns of each cap. Next, the trimming, cleaning

and quality-control process begins.

Finished products are inspected again

before being polybagged, boxed and

shipped.

At sub-assembly stations, the panels are sewn together and eyelets are sewn in as well.

Embroidery is done at the flat-panel stage, as on this back panel. More than 100 embroi-

dery machines run daily at Unionwear.