packing, and then they are stored in the

warehouse, waiting for an order.

“When the order comes in, the art is

transmitted electronically from our art depart-

ment to the label printer, and the next thing

we see is a printed, pressure-sensitive label,

ready to apply to the bottle,” Ellis explains.

“We simultaneously apply the ingredients

statement required by the FDA to the back of

the bottle and the customer art to the front.”

Then, the filled and labeled bottle goes

down a conveyor belt for final inspection, and

one more turn of the cap to ensure it’s on

tight, before the product is dropped in a box

for shipping.

Jen Alexander is an associate editor for

PPB

.

ABOUT HUMPHREYLINE

Founding date

1957

Principals

Bitsy and Mel Ellis

Size of production facility

55,000 square feet

Number of employees

54

Types of specialized equipment

Injection molding;

blow molding; silkscreen printing; pad printing; offset

printing; filling lines for the personal care amenities

line; label making; label printing

Special training is needed to operate any equip-

ment in the plant, and floor supervisors and managers

provide the primary hands-on training. Specialized cer-

tification is required for operating equipment, such as

a forklift truck, and for shipping hand sanitizer, which is

classified as a hazardous material if shipped by air. In

addition, HumphreyLine’s Standard Operating

Procedures (SOP) cover nearly every step in manufac-

turing. In order for an employee to be considered

“trained,” he or she must learn the SOP, take a written

test and agree in writing to follow the SOP.

Number of orders filled per year

20,000

Most popular items

Hand sanitizers, stadium cups and

lip balms

The easiest item to make? The egg flat, used in the

commercial egg industry. It requires no decoration, but

is merely molded and shipped. The most complex? Sand

pails and yo-yos. The steps include molding, decorating

and assembling each piece, all to order for custom color

and decoration options. “Any time you have multiple

manufacturing steps, the complexity rises dramatically—

as does the chance for problems,” says Ellis.

Notable accomplishments

This year marked

HumphreyLine’s 20th consecutive year of shipping more

than 99 percent of its orders complete and on time.

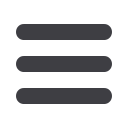

TOP LEFT

A HumphreyLine employee places

empty bottles on the filling line.

TOP RIGHT

Gel sanitizer is dispensed from two nozzles,

each loading 1/4 ounce, into half- ounce bot-

tles.

MIDDLE LEFT

The automatic capper

applies the cap to the top threads of the

filled bottles.

MIDDLE RIGHT

Printed labels

are ready to apply to sanitizer bottles.

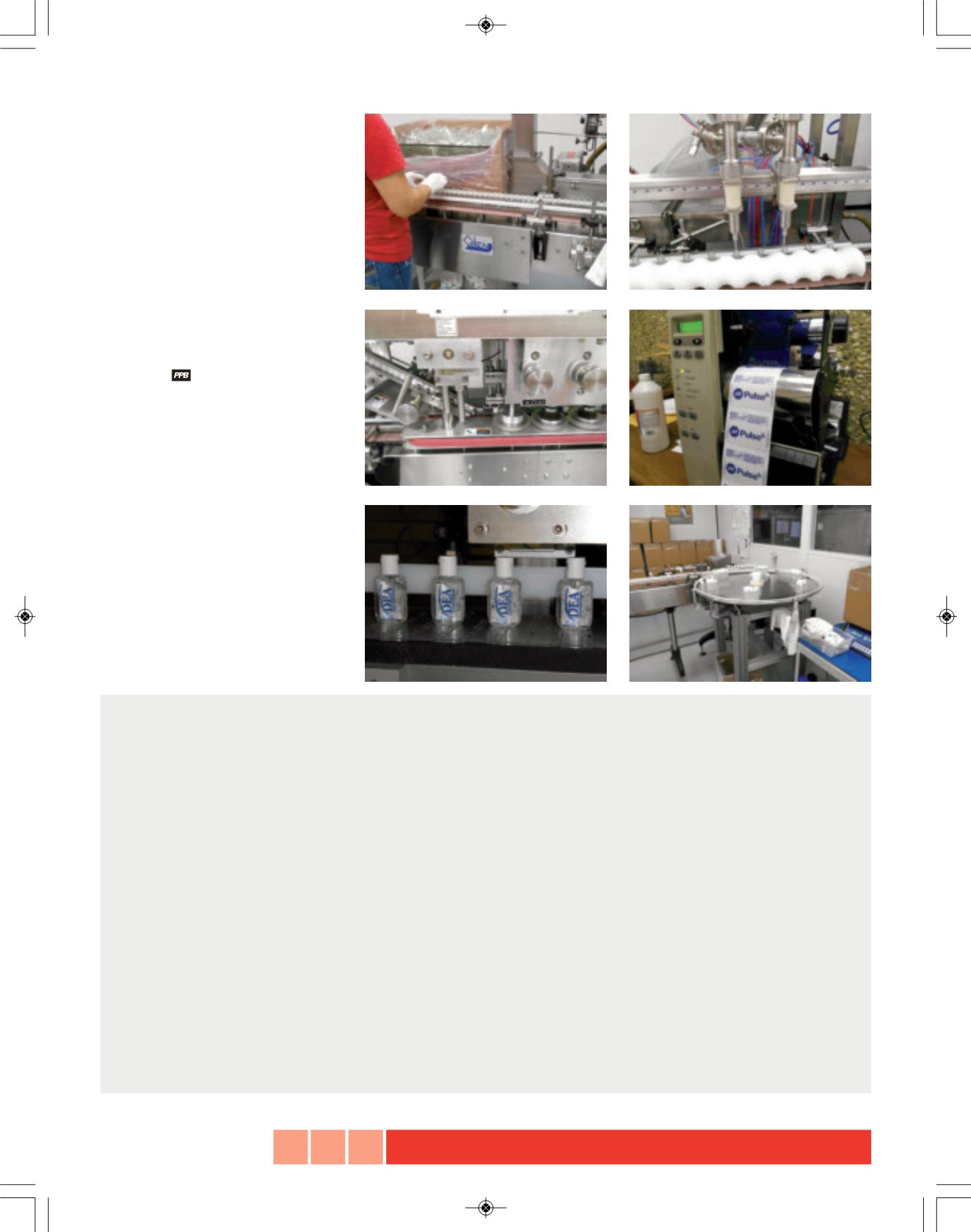

BOT-

TOM LEFT

Labeled bottles of hand sanitizer

glide down the belt at HumphreyLine’s fac-

tory, ready to keep end users healthy.

BOT-

TOM RIGHT

Samples are tested to ensure

the product meets quality standards.

82 •

PPB

• DECEMBER 2014

CONNECT

201412_FactoryFloor_PPB 2013 11/14/14 9:09 AM Page 82